Circular enterprise

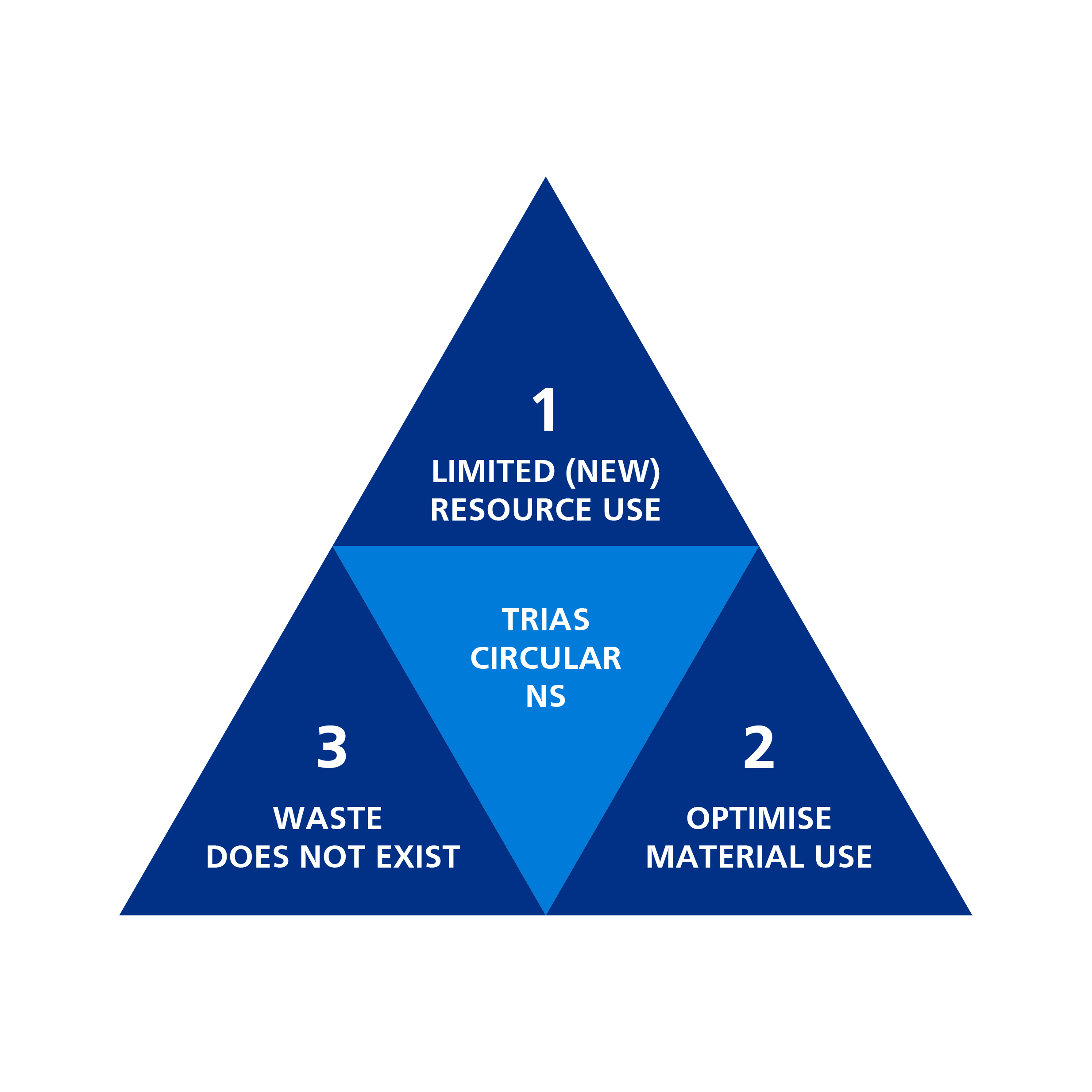

For NS, circular operations mean minimising the use of primary raw materials, maximising the use and reuse of materials and minimising waste in offices, workplaces and from trains. NS Stations – in conjunction with ProRail and the Ministry of Infrastructure and Water Management – strives for waste-free stations by 2040. To achieve that we focus on what we refer to as the ‘Trias Circulair’:

Reduce the use of primary raw materials

Optimise the use of materials

Eliminate waste

Inflow

Reduce the use of primary raw materials

Applying circularity principles in design and procurement will enable us to become smarter in the use of materials and to reduce the use of raw materials. We guaranteed circular procurement through our NS MVOI (Socially Responsible Procurement and Commissioning) policy. See the section on Sustainable Procurement for a more detailed explanation.

Inflow versus outflow

By inflow, we mean all physical resources entering our company. This includes new trains and spare parts, maintenance supplies, company clothing and IT hardware. Inflow is circular if it does not contribute to resource depletion, for example because it has been used before (reused or recycled) or because it is replenished (from a sustainably managed biological source).

By outflow, we mean physical assets leaving our company and the waste thrown away by passengers on trains and at our stations. Outflow is linear if the materials are landfilled or incinerated and circular if the materials are not lost but reused. This only works if it is technically possible to reuse, convert, recycle, ferment or compost those materials and if there is a party that is able and willing to do so.

For definitions of inflow and outflow we align with the World Business Council for Sustainable Development’s Circular Transition Indicators (CTI) framework.

Tendering procedures

In high-impact tendering procedures, we make circularity part of the selection and award criteria. In 2024, this included tenders for charging infrastructure for P&R locations, pantograph components on trains, work platforms for train maintenance and a construction project for the Onnen office.

Material passport

In connection with the purchase and design of New Generation Double-Decker (DDNG) Intercity trains, specific attention is devoted to reducing the weight of the train so that less material is needed to build them and less energy is needed to run them. In addition, the manufacturer shares a material passport of the proposed design. This allows us to jointly select circular materials that do not contribute to resource depletion and can be dismantled and recycled after the train’s lifetime. We are the first party in the world to request a material passport for a new train, and DDNG will thus become the first train worldwide to have a passport of this kind.

Inflow measurement

To effectively manage and promote the circular use of materials, NS applies a permanent ‘inflow measurement’ method that allows us to analyse and record the composition of the materials we procure. In 2024, this covered a total of 14,318 tonnes (2023: 8,420 tonnes). The weight of measured inflow increased. Despite this increase, the relative share of measured inflow fell to 20% (2023: 46%). The reason for this was a sharper increase in the total estimated inflow due to expansion of the scope. Of the incoming materials with a known composition (inflow measurement), 17% were circular (2023: 34%). This decrease is also due to the fact that we now include the retail product range in the measurement. The percentage of circular raw materials in these products is still limited (around 1%).

Sustainable renovation at stations

We are also looking into the possibility of using recycled materials in the construction and renovation of stations to reduce raw materials and material-related CO2 emissions. For example, all materials from the demolished Kiosk at Ede-Wageningen were used for the Kiosk in Venlo. We also looked at how we could transport these materials in the most carbon-efficient way. Another example is Amsterdam Sloterdijk, where 33 luggage lockers have been reused. Recycling therefore not only reduces carbon emissions and raw materials, but also costs.

Outflow

Optimising the use of materials

We take good care of our rolling stock by focusing on effective and sustainable maintenance and timely repairs so as to extend its service life. In 2024, we started preparing to upgrade our 20-year-old VIRM4 double-decker trains so that they can carry passengers for another 20 years. This upgrade process will start at the end of 2025. The aim is to give a second lease of life to 99% of old train components, 83% of which will be refurbished and reinstalled in the upgraded trains.

In our repair and maintenance work, we aim to extend the life of all train components. For instance, 15% (2023: 11% of all train components qualify as ‘reuse components’. This means that in the event of a malfunction, these components are repaired or overhauled rather than thrown away. This helps prevent the need to buy new products and the accumulation of waste.

For condemned public transport bicycles, we have agreements in place with a bicycle manufacturer to take them apart and rebuild them with reused parts. In 2024, 635 bikes were repaired in this way using parts from 1,030 old public transport bicycles. This prolongs the useful life of the public transport bicycle and reduces the need for new bicycles.

Outflow of trains

When a train series reaches the end of its service life, we first examine whether we can keep the train in service for longer by overhauling or upgrading it. If this is not possible, we explore whether we can repurpose the entire train. We sold 72 Intercity coaches and two locomotives to external parties in 2024. We also donated a 'Koploper' type Intercity trainset (ICMm) and two royal coaches to the Railway Museum in Utrecht.

If overhaul or upgrade is not an option, we look at which of the train components we can re-use to maintain our other trains. We dismantled 5,826 components from ICMm trains for our own maintenance activities in 2024.

If we do not use components ourselves, we may offer them for reuse by third parties. We do this by producing and sharing a 'harvest book'. We shared the 'ICMm harvest book' with the market and our partners in 2024. As a result, we were able to dismantle and sell 4,341 train components for reuse this year. In 2024, we set up a train repair shop to increase the quality of both internally reusable and saleable train components.

Finally, once we have reused as much of the trains and train components as possible, we ensure that the remaining train components are separated as much as possible for recycling.

NS Upcycle shops

We opened NS Upcycle Shops at Rotterdam, Weert, Utrecht Central and Ede-Wageningen stations in 2024. The shops sold collectors’ items from trains and NS Upcycle products. In addition to familiar NS upcycle products such as notebooks, serving trays and bags made from old NS materials, this year we also offered new NS upcycle products such as garlands, placemats and coasters. An NS jewellery line made from old NS materials was even introduced in 2024.

NS Auctions

Through eight auctions, we found new uses for old or surplus NS materials in 2024. In total, hundreds of items (and 71.1 tonnes of materials) found a new purpose in this way. In 2024, the KaNScentraal Foundation sold 2.5 tonnes of collectors’ items from our trains to raise funds for projects for disadvantaged children.

Recycling

The circular outflow percentage can be increased through recycling, which is why we redesigned the collection points at NS workplaces and offices. Our aim is to separate more streams. We track the separation rate for each site using dashboards.

Outflow results

In 2024, we disposed of 16,573 tonnes of materials. This is less than in 2023 (27,278 tonnes), due to the fact that we did not upgrade any trains this year and dismantled or sold only a small number of trains.

Eliminate waste

Zero-waste Stations Ambition

To increase the circular outflow of consumer waste at stations, we have improved waste separation in these locations by redesigning our waste collection points and improving knowledge, for example through knowledge exchange sessions on waste separation for our tenants at stations. 56.8% of our waste is processed in a circular way. We also installed the sixteenth reverse vending machine for small PET bottles and cans.

Last year, we extensively reviewed the initiatives from the Zero-waste Stations Ambition over the past three years through behavioural research, waste composition analysis and stakeholder interviews. The results of the review are still being generated and, together with knowledge and experience from similar companies and consultancy firms in the Netherlands and abroad, will form the basis for further steps towards zero-waste stations over the next five years.

Bring your own cups versus disposable cups

Passengers receive a discount on a hot drink at the station when they bring their own cup. In 2024, passengers used their own cup 824,889 times at our own retail chains Julia's, Kiosk and Station Living Room.

At Rotterdam Central this year, NS Stations collaborated with the municipality of Rotterdam and a number of local businesses to carry out a pilot project to examine returnable cups for hot drinks as an alternative to disposable cups. The key lesson is that legislation and a national approach are needed to really make returnable cups a success. The lessons learned are input for the further development of reusable cups in the Netherlands.

Hazardous waste

Hazardous waste made up 6.1% of the total outflow. This includes contaminated water, mineral oils, paints and coolants. We carried out research in 2024 into the impact of hazardous waste and how to reduce and/or prevent it. We used a Strategic Environmental Assessment (SEA) to evaluate the current situation, looking at the amount of waste, the environmental impacts and the costs. Based on the assessment, we examined, analysed and evaluated various interventions to increase the circularity of hazardous outflow.

Knowledge sharing

We have learnt lessons from the circular modernisation and dismantling of our trains and translated these lessons into specifications for the acquisition of new trains. We applied these during the tendering process for the DDNG and S5G type trains. To bring about real change in the market, however, it is important to ensure that other railway businesses also know and apply these lessons. NS is therefore committed to scaling up this knowledge by getting these specifications implemented in Europe through the EuroSpec consortium. This is a collaboration between six European railway companies (NS, DB, SNCF, ÖBB, SBB and RDG) that aims to align needs and specifications in order to reduce costs throughout train lifecycles, reduce delivery times and accelerate innovation. NS developed the train material passport and is the founder of the EuroSpec working group on 'circular specifications for trains'. This working group was set up to standardise circular specifications for the purchase of new trains, such as the material passport, within Europe. In 2024, NS shared the experience and lessons it has gained from applying circular specifications, the material passport and the circular design of DDNG trains during the UIC Circular Economy Sector and Rail Live conference. By requiring the material passport and high recyclability rates, NS is among the leaders in the European railway sector.