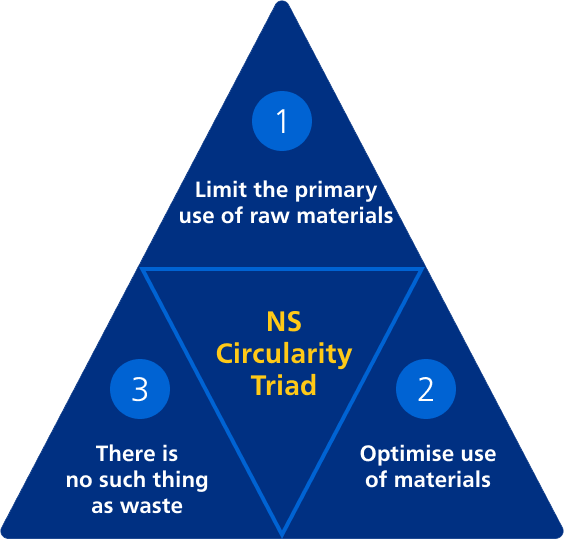

Circular enterprise

NS aspires to achieve full circularity in terms of procurement, maximum reuse of materials and zero waste in offices and workshops and from trains. In this way we contribute not only to the Climate Agreement and the European Green deal, but also to SDG12 and SDG13. In addition, NS - in conjunction with ProRail and the Ministry of Infrastructure and Water Management - strives for waste-free stations by 2040.

Limit the use of primary raw materials

Applying circularity principles in design and procurement will enable us to become even smarter in the use of materials and in reducing the use of primary raw materials. In high-impact tendering procedures, we include circularity as a criterion in the selection and award phase. In 2022 we did so, for instance, in tendering procedures for business uniforms, office furniture and dismantling a workshop in Haarlem. NS measures the circularity of the materials it purchases. In 2022 this covered a total of 7,381 tonnes, or 43% (2021: 70%) of all materials we purchased. Of this volume, 78% was circular (2021: 86%). The figures for 2021 have changed compared with those published in the 2021 Annual Report, due to changes in the method NS uses for this purpose. The fall in inflow can be attributed to the effect of a large infrastructure project in 2021 that involved large volumes of circular materials.

In 2022 we laid down our circular purchasing principles in our MVOI (Socially Responsible Procurement and Commissioning) policy. Inflow measurement (analysing and recording the composition of incoming goods) is now standardised in our purchasing processes and templates, which are available for all suppliers via the NS Procurement website. This year we made the first steps towards automated inflow measurement and enrichment of source data for train-related items with material data. At the beginning of the year, we provided circular purchasing training for NS employees involved in our procurement processes.

We are developing a range of circular products for passengers at our stations in the effort to reduce the use of primary raw materials. For example, we are examining whether single-use packaging is really necessary and only coffee cups with a lid if the passenger specifically asks for one. We also encouraged passengers to opt for reusable cups in a nationwide campaign at our stations in 2022. In that same year, this resulted in a reduction of 178,130 disposable cups at our own formulas Kiosk, Julia’s and Stationshuiskamer.

We are making packaging more sustainable by using renewable and recyclable materials, such as salad trays made from 85% recycled PET. We inspire our partners and suppliers to make further steps in the field of responsible retailing by sharing with them our knowledge and experiences about sustainable and circular purchasing during events and supplier days. In collaboration with our logistics partner Lekkerland we are screening the entire chain for opportunities to make it more sustainable. For example, in 2022 new technologies enabled us to reduce the use of wrap foils by 70%.

Optimum use of materials

We take good care of our materials by focusing on effective maintenance and timely repairs so as to extend their service life. For example, we upgrade our 20-year-old double-decker trains so that they can serve for another twenty years. In 2022 we upgraded 13 double-decker trains with a total of 70 type VIRM2/3 coaches. In this way, 99% of each train is given a new lease of life. We also upgrade 85% of 20-year-old train parts in our components workshop and reintegrate them in our trains for another 20 years of service. Of all materials, we put 13% to new uses elsewhere. For example, we found a new use for 1,100 train windows in the construction of the train wheel repair facility in Leidschendam.

In our repair and maintenance work, we strive to extend the life of all train components. For instance, 11% of all train components qualify as ‘reuse components’. This means that in the case of a malfunction, these components are repaired or overhauled rather than thrown away. This helps us to prevent the need to buy new products and the accumulation of waste.

When a train series is approaching the end of its service life, we identify any components whose life can be extended by reusing them in another series. For example, this year we removed 3,180 train items from our 40-year-old ICMm type Intercity trains and stocked them for reuse in other trains.

There is no such thing as waste

If we have no further use for products and cannot reuse them, we still want to keep them in the cycle as high-value materials. We first try to find a new destination for the product as a whole. If that proves impossible, we find a new destination for separate components. If materials cannot be reused, we separate them for recycling purposes as effectively as possible. In 2022, we appointed a ‘material broker’ who is available full-time to make sure materials are reused as frequently and effectively as possible.

We work with our partners to find new destinations for obsolete NS materials. For example, old upholstery from our trains is turned into shoes, inner tyres of public transport bicycles are turned into travel bags, and departure time displays are turned in birdboxes. In October of 2022 we opened sixth NS Upcycle Shop at Utrecht Centraal, where we sold collectors’ items from trains and NS Upcycle products. This year, our partners collectively sold 3,857 NS Upcycle items. One new feature this year was that visitors to the shop could use train upholstery to make their own pen cases or toilet bags.

For the second year in a row, we found new uses for old or superfluous NS materials via auctions. In total, 392 items (and 45 tonnes of materials) found a new destination in this way. In 2022, moreover, the kaNScentraal foundation sold more than 12 tonnes of collectors’ items from our trains to raise funds for disadvantaged children.

In addition, in 2022, following a tendering procedure we installed bottle return machines at our five large stations. NS is one of the first organisations in the public domain in the Netherlands to use these machines, which are also technically suitable for returnable cans, following legislation that comes into effect in 2023.

All AH to go outlets are partnering with Too Good To Go to prevent food waste. In this way, approximately 111,500 meals are saved every year. The 35% discount sticker on products with a limited shelf-life has enabled us to prevent 113,000 items from being thrown out with the rubbish.

Outflow results

In 2021, NS stopped reporting on ‘waste’ and introduced the concept of ‘outflow’. This means we report on materials that leave our company. This is in line with the CTI measurement method of the World Business Council of Sustainable Development (WBCSD).

In 2022, a total of 24,540 tonnes of materials left our company (2021: 23,924 tonnes). Of the materials that left our company, 63% were either recycled or reused. Hazardous waste makes up 5% of the total outflow. This year we drew up a plan to increase the percentage of circular outflow from our workshops, for example by examining effective ways to reduce the share of hazardous waste.

Promoting the sharing and worldwide upscaling of knowledge

We have learnt lessons from the circular modernisation and dismantling of our trains and translated these lessons into specifications for the acquisition of new trains. We used those specifications in our request for tenders for the new New Generation Double-Decker (DDNG) train series. To bring about real change in the market, however, it is important to ensure that other railway businesses also know and apply those lessons. For that reason we are scaling up those specifications at the European level through Eurospec. NS co-chairs the Circular Economy sector group of the international sector association UIC, in which we work with carriers and infrastructure management companies around the world to achieve full circularity of the railway sector by 2035. In 2022 we organised three sector meetings on behalf of UIC Circular Economy. In addition, we staged the first UIC Zero Waste Workshop in Berlin, sharing best practices in measuring and increasing circular inflow in the railway sector.

Last year, UIC presented the International Sustainable Railway Awards in Berlin. NS won the award in the Circular Economy category and came out as ‘overall winner’ with its project entitled ‘99% Circular Train Modernisation, on the Road Towards 100% Circular Trains in Europe’.